Details Porsche Cayenne and VW Touareg (2002-05/2010) and Gen. II (5/2010-2017)

On Touareg I and Cayenne I access is very easy and the repair can be done even without lifting the car. We do not recommend regreasing the ball bearing as discussed on youtube due to risk for damage of the seal ring if it is removed.

If the center support mount has already been replaced, please check outer diameter of the ball bearing. The OD of the OEM part is about 57mm incl. rubber layer. Some replacement center support mounts occasionally (less than 0,5%) have larger bearings (60mm+rubber) for what we have an oversized repair available.

The outer ring of the OEM mount is rounded at the front side as can be seen at the picture. Third party replacement mounts are typically not rounded what may be a hint for an oversized ball bearing and there have been cases of soft(end) rubber what causes the same symptoms soon after installation but with no damage visible.

In very few cases (less than 2%) we received feedback of vibration between 60 and 80km/h after accomplishment of the repair. In most cases it became much better after about 50km without any action taken. Probably the CV-joint was out of line and stiff/seized enough that the shaft did not center by itself. It may help to push / pull the joint vertically and horizontally in situ. In addition horizontal adjustment of the mount may be an option, but see also below.

In few cases too much rubber remains were left on the outer ring. This causes a tighter fit of the repair ring and slight or moderate vibration may become evident due to reduced dampening.

If there is kind of roaring noise after the repair is done, the standard rubber ring may have been installed (even this is difficult) on an oversized ball bearing (see top section). Then the rubber fit is too tight, slight vibration due to remaining shaft unbalance is accoustically amplified. The 60mm oversized repair is required to fix it.

Another source for roaring noise may be a mount that gets in contact with a tunnel sidewall. There is only approx. 4mm space (each side) and it is recommended to take pictures to verify there is no contact at both sides. If feasible, the mount may be adjusted horizontally, see above.

Sometimes only a zip tie head has migrated sidewards during assembly what may bring the mount in contact with the sidewall. (click on picture to enlarge)

On Touareg / Cayenne II the center support mount has been redesigned by the manufacturer: shifted more backwards, more robust, front protected/shielded,

backup supports, as reliable as on comparable vehicles. If the rubber gets worn

(soft/torn), the 4ea supports get in contact with the rear of the roller bearing (backup, noise), at the beginning when accelerating at higher speeds.

The mount can be accessed, checked and repaired very easily without lifting the car. Our repair is particulary adapted to the redesigned mount: the split rubber ring is hold in position by the outer ring/cage (no retainers needed).

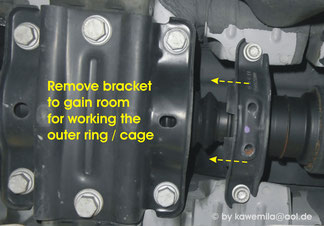

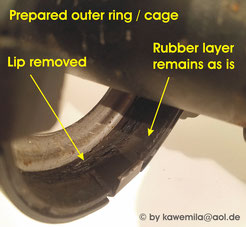

Remove the remaining lip in the outer ring/cage. The 2-3mm rubber layer is kept as is! The bracket in front of the mount

has to be removed to gain some room for working the outer ring. It is recommend to use a sharp blade tip to cut off the lip step by step. This approach is suitable to work behind the 4ea backup supports as well. No need to smoothen the surface.

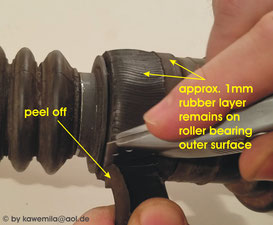

To remove the rubber from the roller bearing start by cutting off some wedges. It is highly recommended to work front to back, to prevent the cuff from being damaged inadvertantly! Now the whole layer may be peeled off. The final diameter shall meet the dimension of the rear part of the bearing (inkl. rubber on it). With the described method the desired about 1mm rubber layer will remain on the outer bearing surface. The repair compensates for any uneveness.

The new split rubber ring is inserted into the outer ring in front of the cuff. It starts with one end on top of the cage. Then it is circumferentially put behind the 4ea backup supports. When seated correctly the whole assy can be slipped over the cuff to finally pull it over the roller bearing. The rectified mount appears OEM like as the repair is made of solid black silicone.